Consumers changed the market trends and BioSafe Systems’ philosophy supported their direction, which provided us the opportunity to partner with customers on an ethical and practical mission.

BioSafe Systems is uniquely structured to ease the transfer of knowledge between departments. We’re invested in a balanced team that combines enthusiasm, active listening skills, and field experience to facilitate an easy flow of intellectual communication between outside and inside representatives. Communication within headquarters has also played an essential role in the progressive applications of our chemistry. We built the Engineering department in 2011 to give BioSafe Systems the opportunity to customize equipment to meet the treatment needs of customers and set the foundation for our Smart Technology.

Our team development has been essential to building and maintaining trusting relationships between customers and the company. Open dialogue inspires and supports the informed answers we provide and our industry partner’s profit. By listening to the daily complications and challenges of our customers’ experience we’ve proven that interpersonal discourse can be the propelling force for necessary innovation.

Our founder, Rob Larose, and his experience in land remediation made him deeply aware of the negative impacts of traditional chemicals. BioSafe Systems’ distinct mission has been to create products that wouldn’t need remediation is a continuous effort to change the mindsets of people who might be hesitant about products because of exhausted green-washing terms. We demonstrate that certifications from regulatory bodies are not for show, you can trust our claims backed by data and endorsed by loyal customers. We’ve carried the green movement into the modern era by introducing North American industries to alternatives and proving their effectiveness. Our products and programs exhibit the evolutions of PAA and integrate other active ingredients and biorationals into traditional programs that strengthen efficacy.

Headquarters are located in East Hartford, Connecticut, where we make sure the sustainable philosophy practiced in the lab and in the field is also reflected in the way we operate at the home base. In 2021, we initiated ISO certifications with National Quality Assurance (NQA), a leading global independently accredited certification body, providing assessments (audits) of organizations to various management system standards since 1988. We’ve achieved accreditation in three distinct ISO management standards; Quality, Environmental, and Health and Safety Management.

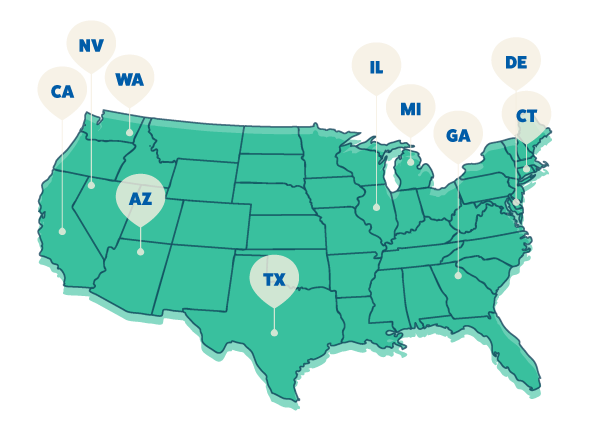

Our responsibility to the planet is at the forefront of our mind. As BioSafe Systems continues to grow, we use and emit more energy. Overall, having multiple manufacturing facilities to cover the nation and the North American market we serve increases on-time availability coast to coast without increasing our carbon footprint or transportation costs.

BioSafe Systems implemented digital business platforms to reduce paper use and material waste and energy. Our facilities use motion-sensing lighting to control electricity output. Our chemistry itself is a vehicle for upcycling whereby adding more of the active ingredient there is less chemical waste, less disposal, and a greater opportunity to return PAA to the distribution cycle. Our mission statement also inspired the assemblage of a Sustainability Committee to further seek opportunities for environmental stewardship and to hold the company accountable to our mission now and in the future.

We have sought out and found cooperative business partners to support our mission. We combined forces with Bee Vectoring Technologies to strengthen our projects and programs in the agricultural biologicals industry. BVT offers biological pesticide alternatives using commercially grown bees. This innovative company takes advantage of the pollination process of bees to provide the foundation for pest and disease management. BioSafe Systems uses sustainable chemistry to control disease and pests, and help with facility sanitation. The partnership is naturally synergistic because these companies share a mission to produce better ways to protect the planet using unique methods. We’ve combined individual specialties to achieve a greater positive impact in both respective fields and on the planet as a whole.

We are the pioneers of peroxyacetic acid (PAA) within agribusiness and have diligently worked to bring the power of PAA to North America. Sustainability and efficacy are the two pillars that we’ve built this business on. But throughout the last quarter-century we have remained steadfast in our mission because our chemistry is successful.

Motivated by rampant toxic chemical treatments, BioSafe Systems’ founding family sought to create the solution every aspect of agribusiness could use, and the planet requires. Learn how the Laroses combined their different skill sets in a grassroots effort to register the first PAA-based chemistry and have been expanding the PAA business nationwide since 1998. Read the full story

We know providing American-Made products is important to our customers to cut down shipping costs and to ensure we meet American quality standards and contribute to environmentally friendly production and a thriving national economy. We manufacture our PAA products in four locations: Coldwater, MI; Cairo, GA; Sparks, NV; and Yuma, AZ, with warehouses in Fresno, CA, and Spokane, WA, strategically located to better serve our diverse customers.

Terms: One entry per person. Continental US only. One grand prize winner will receive a monthly Popcorn Factory subscription ending in December 2023. Two runner-ups will receive one 3-flavor popcorn tin. March 31, 2023, is the last day of entry. Winners will be contacted Monday, April 3, 2023.

Terms: One entry per person. Continental US only. One winner will receive 1,000 cash. December 15, 2023, is the last day of entry. The winner will be contacted on Wednesday, December 20, 2023, via email.

Terms: One entry per person. Continental US only. One winner will receive the Milwaukee 5-Tool Combo Kit. June 30, 2023, is the last day of entry. Winner will be contacted Wednesday, July 5, 2023.